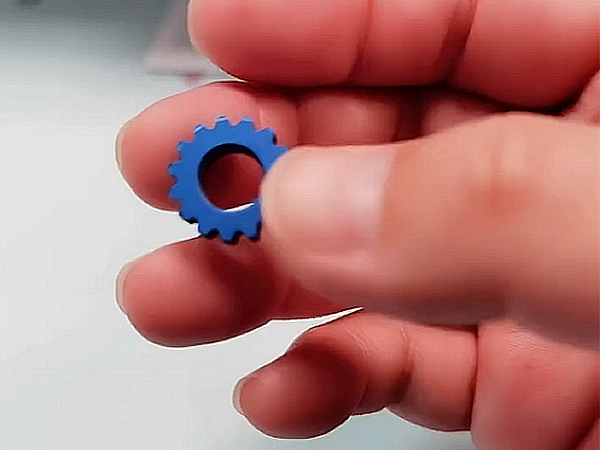

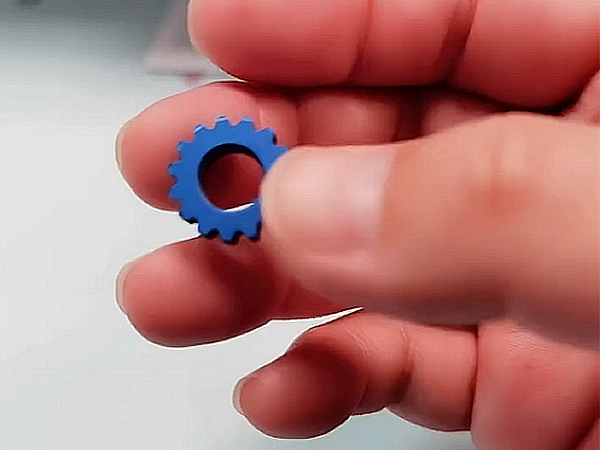

PM aluminum alloy

Part quality: below 30g

1) Weight reduction, corrosion resistance and aging resistance: plastic gear

2) High machining difficulty: gears, gear rings, and irregular parts

3) Performance that conventional aluminum alloys cannot achieve: composite parts

4) Replacing partially pressed sintered stainless steel parts: weight reduction

Hotline: 13600176826

Product details:

PM aluminum alloy is an emerging technology in China, and only a few enterprises in Europe, America, Japan and other countries have mastered it. The company has solved a series of core problems in aluminum alloy powder metallurgy, using self-developed new processes to produce aluminum alloy powder metallurgy products, covering 6 series, 2 series, 7 series aluminum alloys and composite materials. Its mechanical properties are far higher than die-casting aluminum alloys and not lower than machined aluminum alloys, fully utilizing the advantages of high efficiency, low energy consumption and low cost of powder metallurgy, and can achieve commercial production of low-cost and high-performance products. A production line with mass production capability has been built. The target product includes small and micro synchronous wheels, small module gears, end caps, and shaped parts, suitable for product parts that require weight reduction, rust prevention, heat dissipation, and non-magnetic properties. It can be used in fields such as micro transmission, small compressors, lighting fixtures, and drones.

Related products:

Mobile phone: 13600176826

Mobile phone: 13600176826 Contact person: Zeng Hong

Contact person: Zeng Hong Website: www.aluminumpm.com

Website: www.aluminumpm.com Address: Room 101, Building 10, No. 1, Songshanhu Section, Sihai South Road, Songshanhu Park, Dongguan City, Guangdong Province

Address: Room 101, Building 10, No. 1, Songshanhu Section, Sihai South Road, Songshanhu Park, Dongguan City, Guangdong Province